Question: In orthogonal turning of a bar of 100 mm diameter with a feed of 0.25 mm/rev, depth of cut of 4 mm and cutting velocity of 90 m/min, it is observed that the main (tangential) cutting force is perpendicular to friction force acting at the chip‐tool interface. The main (tangential) cutting force is 1500 N.

(i) Determine the orthogonal rake angle of the cutting tool.

(ii) Determine the normal force acting at the chip‐tool interface. [GATE 2013]

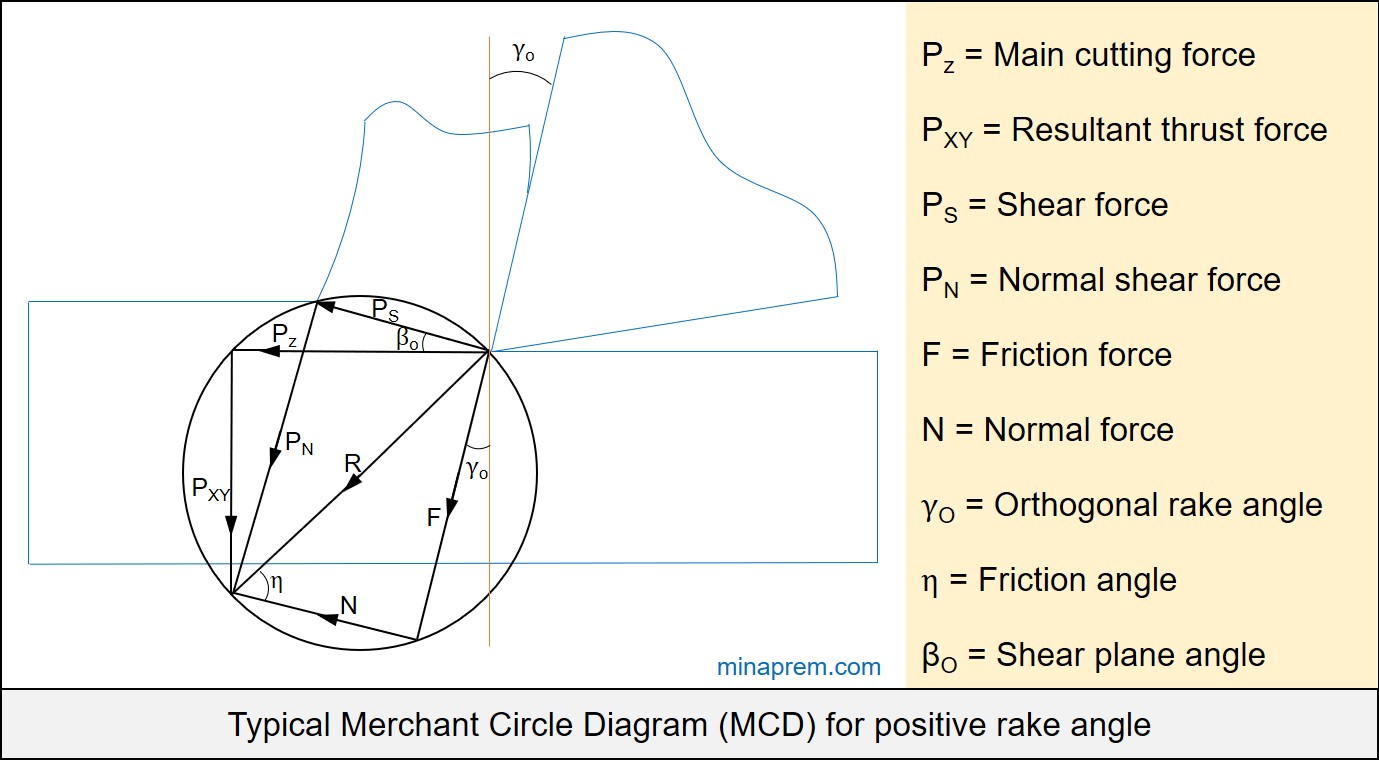

Solution: This problem is a tricky one and has hidden clue along with several superfluous data. No such derivation is required to solve this problem, but a good understanding and visualization of the Merchant Circle Diagram (MCD) are highly desired. The MCD displays various forces associated with orthogonal cutting tool with a sharp edge. A typical MCD for a positive rake angle cutter along with relevant forces is shown below.

Part-1: Calculate orthogonal rake angle

The clue that is given in the question is that the main (tangential) cutting force is perpendicular to friction force acting at the chip‐tool interface. In the above diagram, the main cutting force (PZ) has a fixed direction (i.e. PZ always acts along the cutting velocity vector). However, the friction force (F) acts along the rake surface of the cutting tool and hence depends on the orthogonal rake angle (γO) of the tool. Since rake angle can be either negative, positive or zero, so the direction of friction force also changes accordingly.

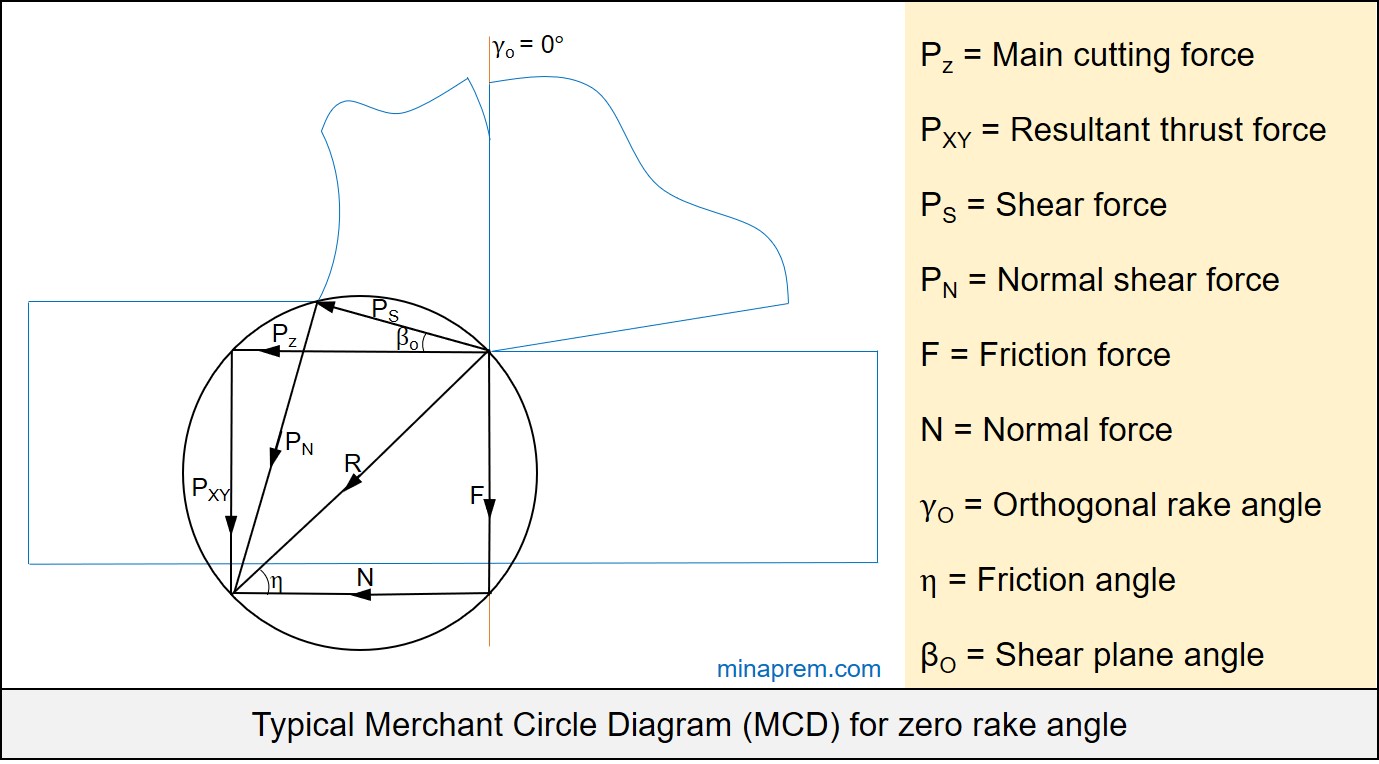

The main cutting force (PZ) becomes perpendicular to friction force (F) only if the orthogonal rake angle (γO) becomes zero. A typical Merchant Circle Diagram for zero rake angle is depicted below. Therefore, the condition given in the question satisfies when orthogonal rake angle is zero. So this gives the conclusion for first part of the problem.

Orthogonal rake angle (γO) of the cutting tool = 0°

Part-2: Calculate normal force

Solution of second part of the question also requires no calculation but a close look and visualization of the MCD. As shown above for MCD with zero rake, four forces—main cutting force (PZ), resultant thrust force (PXY), normal force (N) and friction force (F) together form a rectangle when orthogonal rake angle becomes zero. Therefore, the magnitude of PZ must be same with the magnitude of N. Similarly, the magnitude of PXY must be equal to the magnitude of F. In the question, the main (tangential) cutting force PZ is given as 1500N. Hence, normal force (N) should also be 1500N.

So the normal force acting at the chip‐tool interface = 1500N.