Question: A single point cutting tool with 12° orthogonal rake angle is used to machine a steel workpiece. The uncut chip thickness is 0.81mm. The chip thickness under orthogonal machining condition is 1.8mm. What is the shear angle? [GATE 2011]

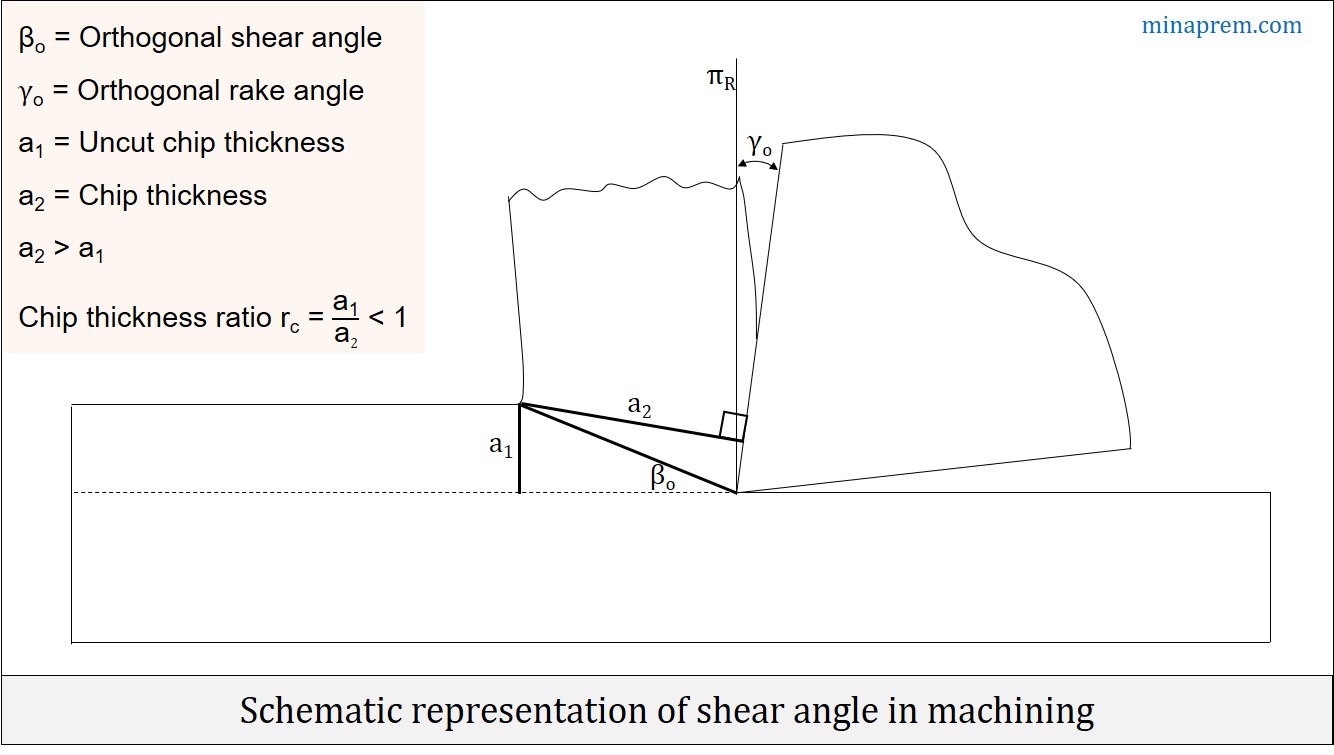

Solution: Machining is one subtractive manufacturing process where layers of material is gradually removed from workpiece by shearing in the form of chips. Shearing actually occurs throughout a 3-D region; however, for the simplicity of analysis, it is assumed that shearing is occurring in a 2-D plane. Inclination of this shear plane from cutting velocity vector is termed as shear angle (βO). For orthogonal machining, this shear angle can be expressed in terms of Chip Reduction Coefficient (ζ) and orthogonal rake angle (γO), as given below.

\[\tan {\beta _O} = \frac{{\cos {\gamma _O}}}{{\zeta – \sin {\gamma _O}}}\]

Chip Reduction Coefficient (ζ) is defined as the ratio between the chip thickness (a2) to the uncut chip thickness (a1). Due to lamellar flow of the chip under cutting strain, chip gets thickened after shearing; and hence, a2 becomes larger than a1. Therefore, ζ > 1. Inverse of the ζ is called chip thickness ratio (rc). From the given values of a1 = 0.81mm and a2 = 1.8mm; let us first calculate Chip Reduction Coefficient. So, ζ = (a2/a1) = (1.8/0.81) = 2.22. Now let us apply the above formula of shear angle using the given value of orthogonal rake angle γO = 12°.

\[\tan {\beta _O} = \frac{{\cos 12}}{{2.22 – \sin 12}} = 0.486\]

\[{\beta _O} = 25.92\]

Therefore, shear angle in the given case is 25.92°.