Abrasive jet machining is one of the advanced machining processes that utilizes a high velocity jet of fine abrasives (10 – 50µm) accelerated in pressurized gas to erode material from work surface. It can provide surface roughness (Ra) down to 200µm and tolerance of ±100µm. Maintaining accuracy (roughness, dimension, tolerance, and other surface characteristics) in AJM is quite difficult task as a large number of parameters influence the process. Any deviation in machining parameters from their corresponding optimum level may lead to inaccurate machining (and thus rejected parts). However, stand-off distance (SOD) is considered as paramount factor for dimensional inaccuracy of machined features.

Reasons for Inaccuracies in Abrasive Jet Machining

Effect of stand-off distance (SOD)

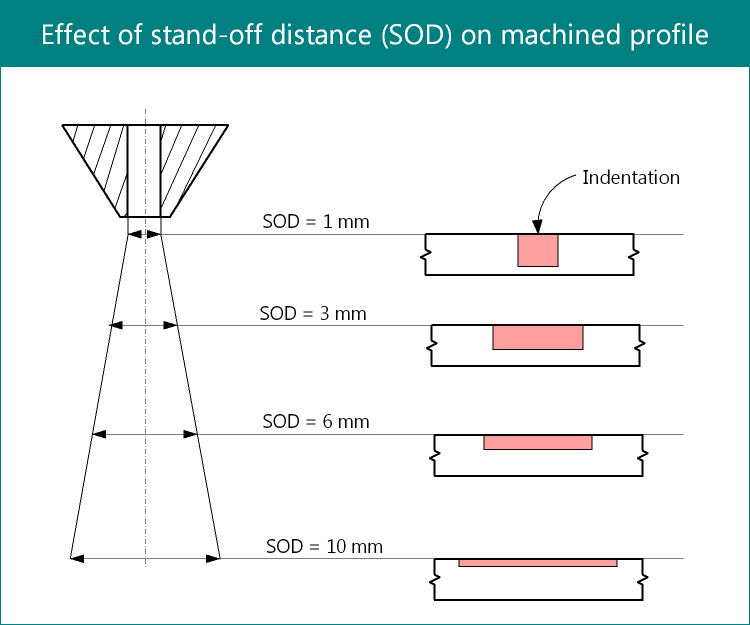

Stand-off distance is the dominating parameter in abrasive jet machining when attention is focused on the accuracy of machined profile. Basically the gap between nozzle tip and work surface is called Stand-Off Distance (SOD) or Nozzle Tip Distance (NTD). After leaving the nozzle, high velocity (100 – 300m/s) abrasive jet travels through this gap before it strikes the work surface. During this travel, the jet experiences much lower surrounding pressure and thus it starts diverging.

As a result, cross-sectional area of the jet increases with increase in SOD. As flow rate is fixed, increase in cross-sectional area implies reduction in jet velocity, and thus kinetic energy of jet degrades with SOD. As a consequence, jet having wider area but low kinetic energy participates in erosion. So the machined channel will be shallow but wide. Reverse shape of profile (deep and narrow) can be observed when SOD is small. Thus, any anomaly in SOD can lead to dimensional error of the abrasive jet machined features. Following diagram illustrates variation in channel depth and width with SOD.

Effects of other parameters on machining accuracy

Abrasive grain size—Crater size depends on average diameter of abrasives. Larger grits create large size cavity or indentation. Fine abrasives can provide better surface finish. Agglomerated abrasives, foreign particles, etc. can also cause variation in process parameters leading to inaccuracy. Therefore inaccurate selection of abrasive size can lead to inaccurate machining in terms of surface roughness, tolerance and corner radius.

Gas pressure and flow rate—Carrier gas pressure and flow rate determines jet velocity. Usually based on jet velocity and estimated MRR, feed rate is selected. Thus any variation in gas pressure or flow rate may lead to inaccurate cutting.

Nozzle diameter and wear—Along with SOD, cross-sectional area of the nozzle regulates kerf width of the machined features. However, nozzle undergoes gradual wear and thus diameter increases. As wear advances, kerf width also increases, which promotes inaccurate machining.

Impingement angle—90º impingement angle can cut deeper and narrow slots or holes. Any deviation from 90º can prompt inclined and improper cutting.

Material properties—If material is not homogeneous then MRR can vary for same process parameters. So surface treatment, residual stress, surface asperities, etc. can also trigger inaccuracy of abrasive jet machined features.

References

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Book: Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).