Mathematical formula for material removal rate (MRR) in abrasive jet machining (AJM) can be modeled by equating kinetic energy of each abrasive particle with the energy required for creating an indentation of certain cord length on a specific material. On the basis of few assumptions, MRR can be estimated both for ductile materials and for brittle materials, as they behave differently in crater formation. You can read these assumptions as well as entire modeling by clicking the corresponding links. The following sections display final formulas for MRR and their significance.

- Read more: Assumptions considered for modeling MRR in AJM.

- Read more: Establish analytical formula for MRR in AJM (modeling).

Formulas for MRR in abrasive jet machining

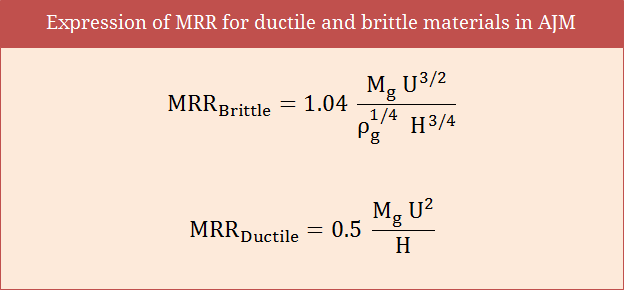

Since crater formation by the impact of single grit in ductile material is different from that of brittle material, so MRR will also be different as given below. Notations used in the expression and their meaning are also provided here.

$$∴{MRR_{brittle}} = 1.04{{{M_g}.{U^{3/2}}} \over {{\rho _g}^{1/4}.{H^{3/4}}}}$$

$$∴{MRR_{ductile}} = 0.5{{{M_g}{U^2}} \over H}$$

- U = Velocity of abrasive jet at the point of impact.

- H = Flow strength or hardness of the work material.

- Mg = Mass flow rate of abrasive particles.

- ρg = Density of each abrasive particle.