In abrasive jet machining (AJM), a high velocity (100 – 300m/s) jet of abrasive grits accelerated by dehumidified pressurized gas (called carrier gas) is made to strike the work surface to gradually remove material. It is considered that work material is removed mainly by erosion and sometime assisted by brittle fracture caused by the impact of fine abrasive grits (size between 10 – 50µm). Types of abrasive as well as its shape, size and other properties influence machining capability. Aluminum oxide (Al2O3), silicon carbide (SiC), sodium bicarbonate (NaHCO3), and glass beads are commonly used abrasives in AJM. Desired properties of abrasives for AJM are enlisted below.

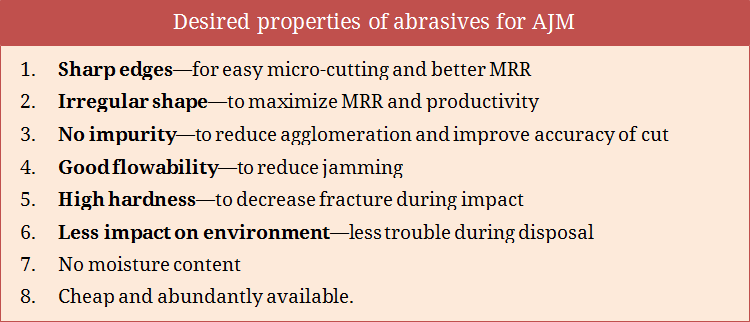

Desired properties of abrasives for abrasive jet machining

Abrasive grits must have sharp edges—for easy micro-cutting action. Although for modeling purpose grits are assumed to be of spherical shape, practically sharp edges are indispensably necessary otherwise MRR will be low and surface finish will be poor.

Abrasive grits should have irregular shape—but variation of size within the overall mass should be low, otherwise assessment of MRR and surface quality will not match. Larger grit creates larger cavity and thus high MRR with poor surface finish is obtained, while smaller grits tend to remain embedded on work surface leading to poor surface finish.

Abrasive grits must not contain metal particles—as it can cause blockage in the pipeline. That is why reuse of abrasives is not recommended.

It must have good flow characteristics—for smooth flow in the pipeline when mixed with carrier gas.

It should have high hardness—and should be rigid enough so that it does not crumble into parts when striking the work surface. Different abrasives produce different MRR as their hardness values are different.

Abrasives must not contain moisture—otherwise after mixing with compressed air, moisture may condense, which can severely hamper flow characteristics.

It should be cheap and readily available—this is the obvious reason for minimizing production cost.

Various abrasives used in AJM

Abrasives are usually selected on the basis of application while average grit size is selected based on the surface finish requirement. Although aluminum oxide (alumina—Al2O3) and silicon carbide (SiC) are two frequently used abrasives, there exist quite a few other abrasives that are used for various purposes to obtain better result. A list of abrasives and their application areas are enlisted below. You may also read: Compare various types of abrasives used in AJM process.

- Aluminum Oxide (Al2O3)—Alumina is used for cleaning, cutting and deburring purposes for moderate to hard materials.

- Silicon Carbide (SiC)—It is harder abrasive compared to alumina. Thus can be used for all the above purposed but for very hard work materials. Silicon carbide can reduce the nozzle life.

- Glass beads—This is mainly used for producing matt surfaces for reducing transparency.

- Crushed glass—For heavy cleaning, matting and peening operations.

- Sodium Bicarbonate (NaHCO3)—Baking soda is commonly used for light duty applications such as cleaning, cutting, etc. on soft materials.

References

- Book: Nontraditional Manufacturing Processes by G. F. Benedict (Taylor & Francis).

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).