For any machining or metal cutting operation, three relative motions between the workpiece and cutting tool are indispensably necessary for gradual removal of material from the workpiece. In fact, the simultaneous action of all three relative motions causes advancement of cutting tool towards work material along the intended path generating a finished surface with intended shape, size and tolerance. These three relative motions are called Cutting Parameters.

There process parameters in machining are all those parameters that are inherent to any machining operation and should have a suitable finite value to smooth and efficient removal of materials. Such parameters directly affect machining performance. In machining, three process parameters are (i) cutting speed or cutting velocity, (ii) feed rate and (iii) depth of cut. More details about these parameters are elaborated in the following sections.

Process Parameter – 1: Cutting velocity (Vc)

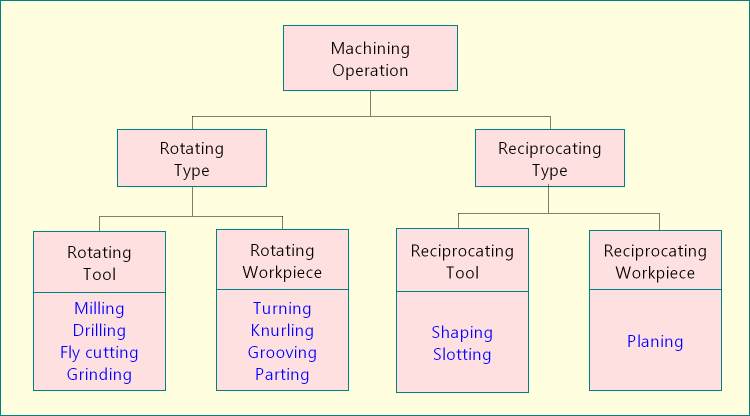

Cutting velocity is the most important cutting parameter that provides necessary cutting motion (CM). In case of either rotating tool (such as milling, drilling, grinding) or rotating workpiece (such as turning), the peripheral velocity of cutter or workpiece (as the case) is considered as the cutting velocity. The rotational speed is called the Cutting Speed (denoted by N and measured in rpm); whereas, the tangential velocity is called Cutting Velocity (denoted by Vc and measured in m/min).

However, where neither the workpiece nor the tool rotates, the reciprocating velocity of cutter/workpiece gives the intended cutting velocity. In such contexts, cutting speed becomes irrelevant. Therefore, cutting velocity imparts main or primary cutting motion required for machining.

Process Parameter – 2: Feed rate (s)

The auxiliary cutting motion is provided by the feed rate or feed velocity. Usually the direction of feed velocity is perpendicular to that of the cutting velocity; however, not necessary. The primary objective of feed velocity is to advance the cutter with respect to the workpiece to remove material from a wider surface. Basically it helps in covering the entire surface of the workpiece by moving either cutting tool or workpiece. Feed rate can be imparted either on the cutter or on the workpiece.

Process Parameter – 3: Depth of cut (t)

The tertiary cutting motion that provides necessary depth within work material that is intended to remove by machining. It is given in the third perpendicular direction and the simultaneous action of three cutting parameters results in removal of excess material from workpiece.

Features of process parameters

- It must be primary factor i.e., there should not be any other factor that controls it.

- It must be supplied during machining.

- It should have a finite value.

- It should directly affect machining performance.

- It can be varied externally without changing the work-tool combination.

Process parameters differ from influencing parameters

Influencing parameters include all those parameters that can directly or indirectly influence the machining operation. Thus all process parameters are influencing parameters. Apart from velocity, feed and depth of cut, there are many other parameters that can influence performance considerably; however, they are not inherent to machining process. A list of such parameters relevant to conventional machining is provided below.

- Cutting environment (i.e., application of coolant)

- Tool geometry including nose radius

- Work material

- Tool material

- Tool coating

- Work and tool setting, etc.