The angle between the face and flank surface of a single point cutting tool is termed as lip angle or wedge angle. There exist another confusing angle called point angle, which is the angle between principal cutting edge and auxiliary cutting edge. Lip angle is the angle between the rake surface and flank surface when viewed on orthogonal plane. Point angle is the angle between the principal cutting edge and auxiliary cutting edge when viewed on reference plane. Lip angle and point angle are independent. They cannot be visualized in same plane also. None of them are mentioned in tool signature.

What is face of the tool? Rake surface of the cutting tool is also termed as tool face. Inclination of this surface from reference plane is measured by rake angle (γ). This angle has immense importance in machining performance. Chip that is generated during machining flows over the face of the tool before it leaves the machining zone. There always exists physical contact between the flowing chip and face of the tool, and thus intense rubbing takes place. The region surrounding this contact area is termed as Secondary Deformation Zone. This zone is the primary source of cutting heat. About 70 – 80% of the total cutting heat is generated from this zone.

What is flank surface of the tool? Flank surface or clearance surface is another important surface of the cutting tool that is associated with the machined surface (rather than chip). A gap must be maintained between the flank surface of the tool and finished surface of the job. This angle is termed as clearance angle (α). A single point tool contains two flank surfaces – principal and auxiliary. Intersection of principal flank surface and rake surface leads to the formation of main cutting edge; whereas, auxiliary cutting edge exists at the intersection of auxiliary flank surface and rake surface.

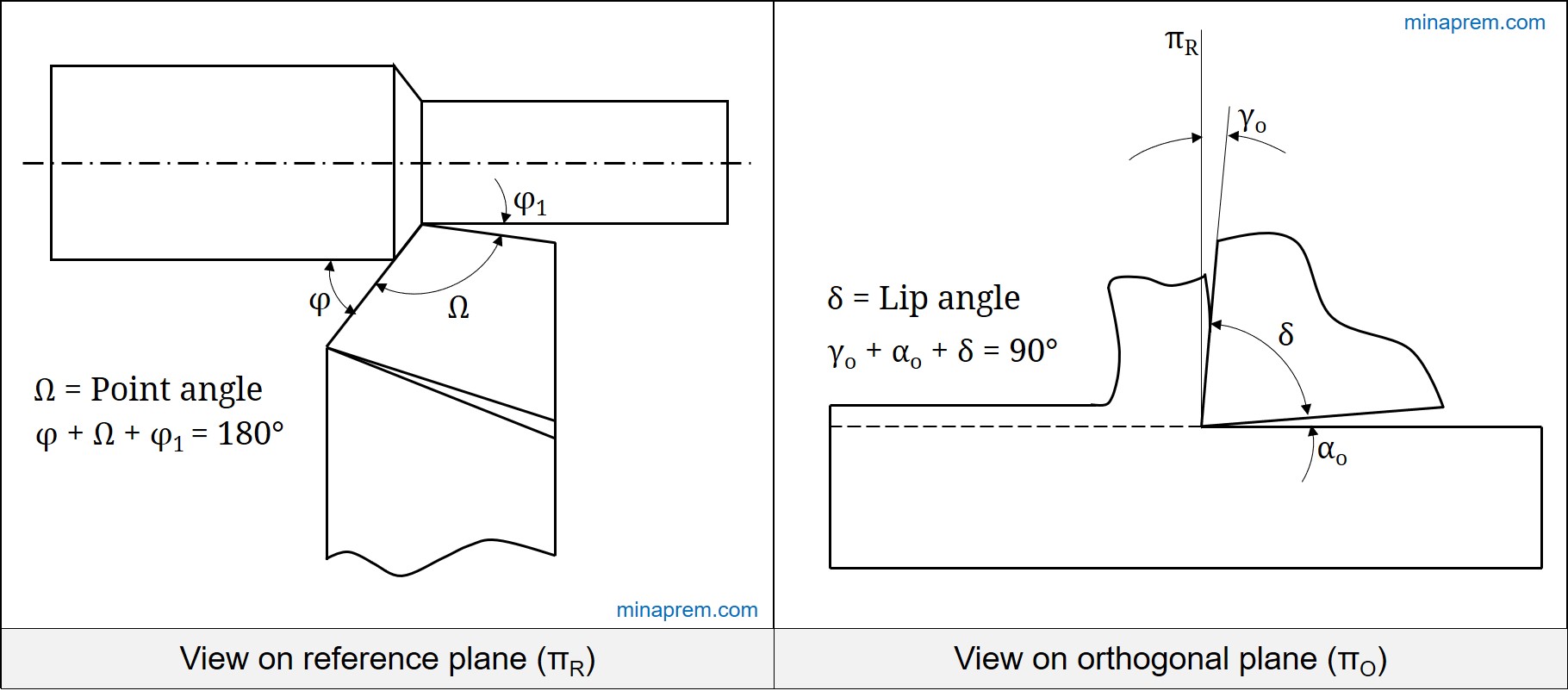

Relation among rake, clearance and lip angles: These three angles can be illustrated together by the sectional view of a typical single point cutting tool on the orthogonal plane (see figure). Among these three angles, the rake angle can be either negative, zero or positive; whereas, other two angles are always positive. Algebraic sum of these three angles must be equal to 90°. Therefore, if orthogonal rake angle is denoted by γo, orthogonal clearance angle is denoted by αo, and lip angle is denoted by δ, then the algebraic sum (γo + αo + δ) = 90°.

Relation among principal and auxiliary cutting angles with point angle: In order to visualize point angle, sectional view must be taken in reference plane. Three adjacent angles, namely principal cutting edge angle (Φ), auxiliary cutting edge angle (Φ1) and point angle (Ω) can be observed in this view. For a turning tool, these three angles are always positive but below or equals to 90°. However, sum of these three angles must be equal to 180°, that is (Φ + Φ1 + Ω) = 180°.