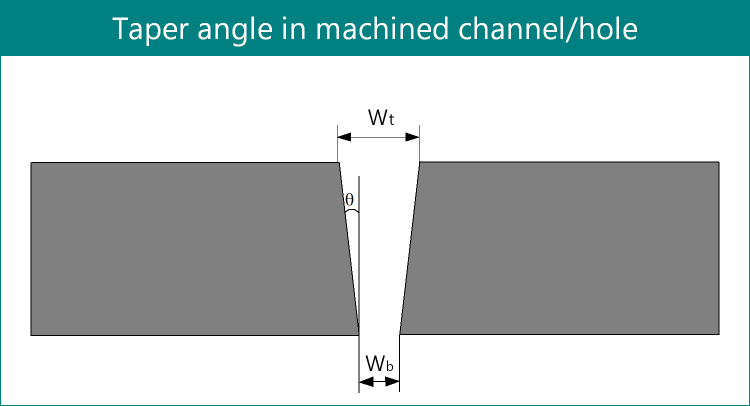

Getting perfectly vertical walls is difficult by abrasive jet machining. Slots or holes machined by AJM become tapered shape, especially when plate thickness is above 3mm. Profile of machined features usually changes because of jet flaring and consequent loss of kinetic energy. Kerf width sometime becomes larger than jet diameter as coming out abrasive grits also erode material from side walls. Determination of this taper angle is absolutely necessary for getting an idea about the level of accuracy and tolerance achievable by the process under certain conditions. This taper angle can be analytically determined using few geometrical parameters under some assumptions, as elaborated below.

Assumptions for determining taper angle in AJM

- The hole or slot is of taper shape having straight but inclined walls. This is contrary to the practical situations as parabolic profiles are commonly encountered in machined holes or slots.

- The taper angle is uniform. Incremental or detrimental rate of taper angle is constant over the entire depth.

- In case of machined slot or channel, both sides have same taper angle.

Notation used in this analysis

- Wt = Width of the slot or hole at top surface (measured on a cross-section)

- Wb = Width of the slot or hole at bottom surface (measured on the same cross-section)

- t = Depth of the slot or hole

- θ = Taper angle to be measured

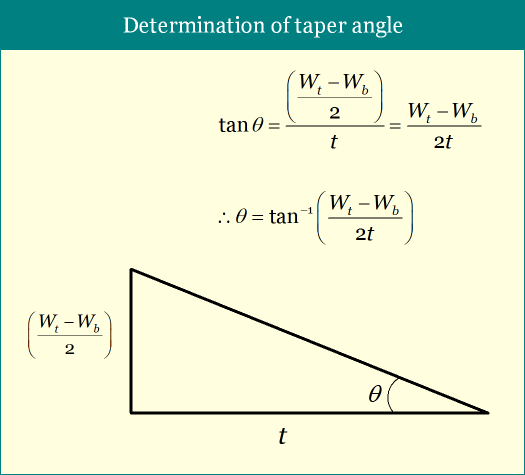

Determination of taper angle of machined slot or hole

If we concentrate our focus on only one inclined side of the cross-section of machined slot or hole, the following diagram can be drawn. Further applying simple trigonometric formula, the taper angle can also be determined as shown within the figure. Take care of the 2 at the denominator, which students sometime forget to consider. You may try solving the below example.

Example for determination of taper angle of drilled hole

Question: While drilling a cylindrical hole of desired diameter 750µm and aspect ratio is 5:1 using abrasive jet machining (jet diameter = 750µm), it was finally observed that hole diameter at top surface is 50µm larger than jet diameter, while that in bottom surface is 60µm lower than jet diameter. Determine the taper angle of the hole.

Solution: Here jet diameter is 750µm. So diameter of hole at top surface is 800µm and the diameter of hole at bottom surface is 690µm. Again, aspect ratio is 5:1 and desired diameter 750µm. Since aspect ratio is the ratio between length and diameter, so length of the hole is 5×750=3750µm. Therefore,

- Wt = 800µm

- Wb = 690µm

- t = 3750µm

- θ = ?

We know, tanθ = (Wt – Wb) / 2t

Or, tanθ = (800 – 690) / (2×3750)

Or, tanθ = (110) / (2×3750)

Or, tanθ = 0.0147

Or, θ = 0.84º

Therefore, taper angle of the abrasive jet machined slot is 0.84º.