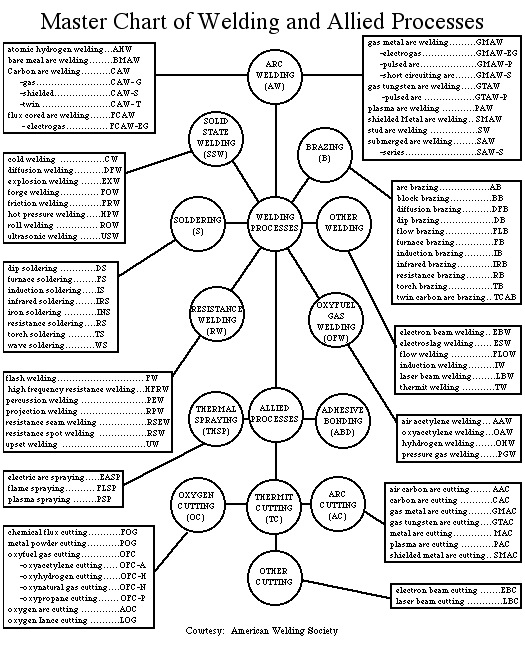

The arena for welding is vast. In order to cater the need for joining a wide variety of materials in multifarious ways, a large number of welding techniques are available; each of them has certain unique features, pros and cons with respect to others. Now-a-days, more than 100 different welding processes are conventionally used. Grouping all of them is a bit difficult. Any concise classification will have some lacuna that can left out few processes from a particular group. This paves the way for classifying welding processes in different ways, as described below.

- Read more: Definition of welding.

- Read more: Advantages and disadvantages of welding joint.

Way-1: Classification of welding processes based on whether base material is melting or not

Fusion Welding—To accomplish welding, either heat or pressure is required to apply from external source. When heat is applied externally, subsequent melting of base material takes place, which upon cooling produces a sound joint. This type of welding process where faying surfaces of base material melt down is known as Fusion welding. It may or may not take external filler material, and thus it can be further classified into three categories—Autogenous, Homogeneous and Heterogeneous welding, as discussed in Way-2. All types of arc welding and gas welding processes come under fusion welding category.

Solid-State Welding—When pressure is applied externally, instead of applying heat, then it is termed as solid-state welding. However, in this process heat may produce internally that can elevate the temperature of base materials (but base materials don’t fuse as temperature remains lower than melting temperature). Here usually filler materials are not applied (autogenous welding). Resistance and diffusion based welding processes usually come under this category.

Way-2: Classification of welding processes based on need and type of filler material

Autogenous Welding—In all fusion welding processes, external filler material may not necessary. If welding is done without any external filler material, then it is termed as Autogenous welding. So here base material itself melts down and produces intended weld bead. Solid state welding processes are mostly autogenous. Learn more about autogenous welding.

Homogeneous Welding—On the other hand, if external filler material is applied during fusion welding and the metallurgical composition of filler material is same with that of base material, then that welding is termed as Homogeneous welding. Learn more about homogeneous welding.

Heterogeneous Welding—Again, if external filler material is applied during fusion welding but metallurgical compositions of filler material and base materials are substantially different, then that welding process is termed as Heterogeneous welding. Proper care must be taken before conducting heterogeneous welding to check whether filler material is compatible with base materials or not. If they are not compatible, then result will be a defective welding. Learn more about heterogeneous welding.

Way-3: Comprehensive classification of welding processes

- Arc Welding

- Manual Metal Arc Welding (MMAW)

- Gas Metal Arc Welding (GMAW)

- Tungsten Inert Gas (TIG) welding

- Submerged Arc Welding (SAW)

- Flux Cored Arc Welding (FCAW)

- Electro Slag Welding (ESW)

- Atomic Hydrogen Welding (AHW)

- Stud Arc Welding (SW)

- Gas Welding

- Air-Acetylene Welding (AAW)

- Oxy-Acetylene Welding (OAW)

- Oxy-Hydrogen Welding (OHW)

- Pressure Gas Welding (PGW)

- Resistance Welding

- Resistance Spot Welding (RSW)

- Resistance Seam Welding (RSEW)

- Percussion Welding (PEW)

- Flash Welding (FW)

- Upset Welding (UW)

- Solid-State Welding

- Cold Welding (CW)

- Roll Welding (ROW)

- Diffusion Welding (DFW)

- Forge Welding (FOW)

- Friction Welding (FRW)

- Explosion Welding (EXW)

- Ultrasonic Welding (USW)

- Thermo-Chemical Welding

- Thermit Welding (TW)

- Intense Energy Welding

- Plasma Arc Welding (PAW)

- Electron Beam Welding (EBW)

- Laser Beam Welding (LBW)

- Read more: Complete list of welding processes.

Way-4: Classification of welding processes based on utilization of automated system

Manual Welding—Here entire welding operation is performed by human operator (welder). So quality of welded joint depends on experience and capability of welder. It lacks consistency and is subject to human error. It is also time consuming, but flexible. Manual Metal Arc Welding (MMAW) is commonly performed by human workers.

Semi-Automated Welding—Here automation is applied to perform some task and rest is done manually. So it takes advantages of both automation and manual operations. For example, Tungsten Inert Gas (TIG) welding can employ a feeder vehicle to hold the torch and move it at a constant speed, while filler material can be fed manually.

Automated Welding—Fully automated by means of Computer Numerical Control (CNC) systems and robotics. It is less flexible but highly productive. Human operators are also required to monitor the entire system and take suitable decisions in emergency situations. Laser and electron beam welding processes utilize fully automated set-up. Fully automated welding is commonly employed in automobile industries.