In abrasive jet machining, kinetic energy of high velocity abrasive grits is utilized to erode material in solid form. The carrier gas accelerates these fine abrasives and also assists to blow away eroded particles from machining zone. Although AJM is used mainly to get a smooth surface (instead of bulk material removal) by removing a thin layer of material from work surface, erosion rate or material removal rate (MRR) is one of the crucial factors (other factors are nozzle life and machining accuracy) to assess the performance of process.

Improved MRR without sacrificing product quality and nozzle life is highly advantageous from economic point of view as it considerably enhances productivity. This indirectly helps industry in acquiring goodwill (an important asset for any company) by delivering products in timely manner. However, improving MRR is not an easy task as many controllable and uncontrollable parameters affect the erosion capability in AJM. Various possible ways of improving material removal rate in abrasive jet machining along with limitations are discussed in the following sections.

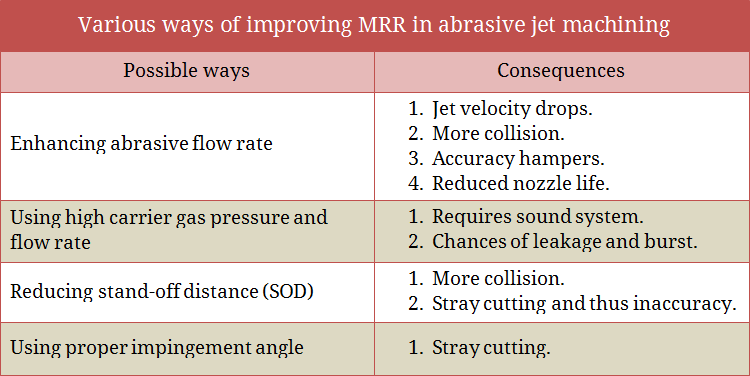

Various ways of improving MRR in abrasive jet machining

Enhancing abrasive flow rate

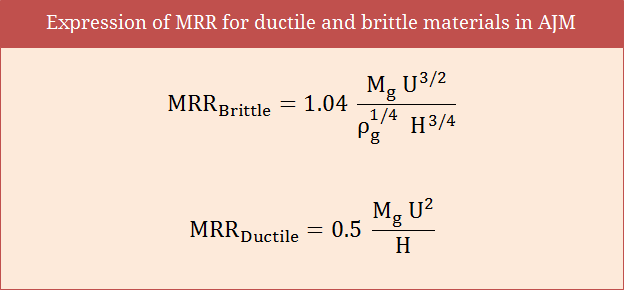

It is evident from analytical model of material removal rate in AJM for ductile or brittle materials that MRR is proportional to abrasive flow rate. As usual, increased abrasive flow rate can lead to palpable improvement in erosion rate as more number of abrasives will impinge the work surface per unit time.

However, final velocity of jet reduces since carrier gas flow rate and pressure are kept unchanged. Consequently, jet quickly losses its kinetic energy because of spreading while moving through stand-off distance (SOD), and ultimately erosion capability degrades. A steady enhancement in MRR can be noticed if gas flow rate and pressure are also increased with abrasive flow rate; however, such actions depend greatly on set-up capability as tight joints, thicker pipelines, strong structures, etc. are absolutely necessary to withstand high pressure without failure.

Using high carrier gas pressure and flow rate

As discussed earlier, a high gas flow rate gives provision of utilizing high abrasive flow rate and thus enhancing material removal rate without sacrificing machining quality and nozzle life. For same mixing ratio and nozzle diameter, velocity of abrasive jet can also be increased by increasing carrier gas pressure. However, every set-up has certain limitation and rated capability beyond which gas pressure cannot be increased.

Reducing stand-off distance (SOD)

When gas-abrasive mixture jet moves through SOD (gap between nozzle tip and work surface) it experiences substantially lower surrounding pressure and consequently it starts spreading leading to increase in diameter and loss of velocity. When jet strikes workpiece after passing though longer SOD, it lacks kinetic energy to efficiently erode material. On the contrary, when SOD becomes very small, abrasives don’t get sufficient passage to leave machining zone and thus fresh abrasives collide with used abrasive that leads to loss of velocity, lower erosion rate and also machining inaccuracy. Thus an optimum SOD can fetch better MRR.

Using proper impingement angle

In most of the cases a vertical jet (impingement angle = 90º) provides better result; however, in many instances it was observed that 70º – 80º angle gives maximum MRR. Although it depends on many other factors, in general any deviation in impingement angle from 90º can lead to machining inaccuracy. Also an angle of below 60º can considerably degrade material removal rate.

There exist many other factors that can influence erosion rate in AJM, for example, size and strength of abrasives, mechanical properties of work surface including strain hardening and residual stress, diameter and wear rate of nozzle, type of cutting, type of carrier gas, etc. Therefore it is been observed that enhancing material removal rate (MRR) in abrasive jet machining (AJM) is one challenging task because of its dependency on many controllable and uncontrollable factors. An optimization considering various constraints arising from machine set-up, process parameters, requirements, work material and abrasive properties, etc. can provide a better solution for a specific scenario.