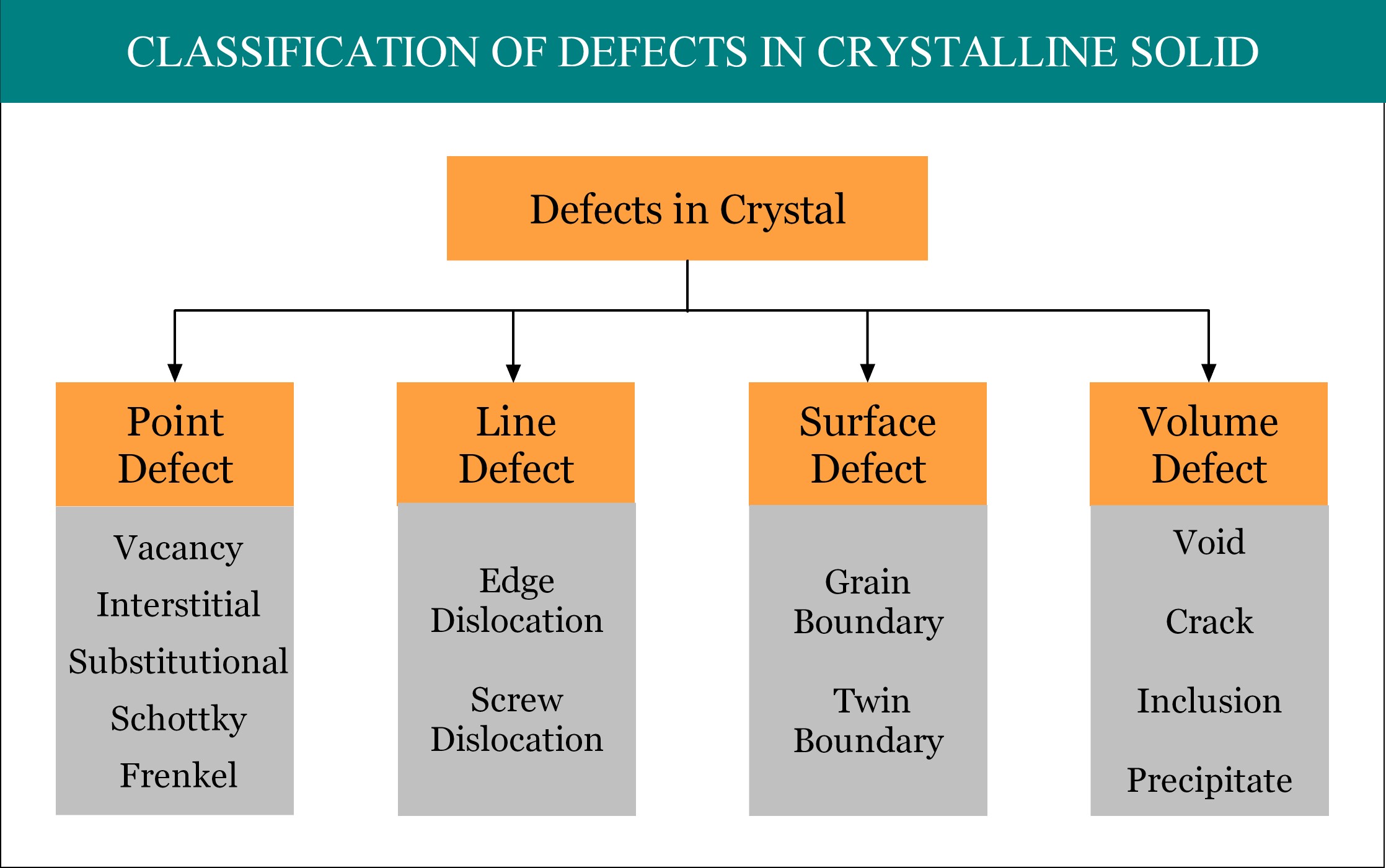

Imperfections or defects in crystalline solid can be broadly classified into four groups, namely, point defect, line defect, surface defect and volume defect. Point defect is considered as the zero dimensional (0-D) defect, as by mathematical definition, a point is unit-less dimensionless quantity! A point defect occurs when one or more atoms of a crystalline solid leave their original lattice site and/or foreign atoms occupy the interstitial position / lattice site of the crystal. There are several types of point defects and interstitial is one of them.

Concept of crystalline solid:

Crystalline solids are those where atoms or molecules or ions are arranged in a regular pattern (known as crystal lattice) that extends in all directions. So crystal lattice is a highly ordered three-dimensional structure of atoms or molecules or ions. If the arrangement of atoms or molecules or ions is highly irregular, then the solid is termed as Amorphous. In between there exist Polycrystalline solids, where few different crystal lattices are observed within same solid. Diamond and Salt are common example of crystalline solid; whereas, Wax, Glass, etc. are amorphous.

What is interstitial defect in solids?

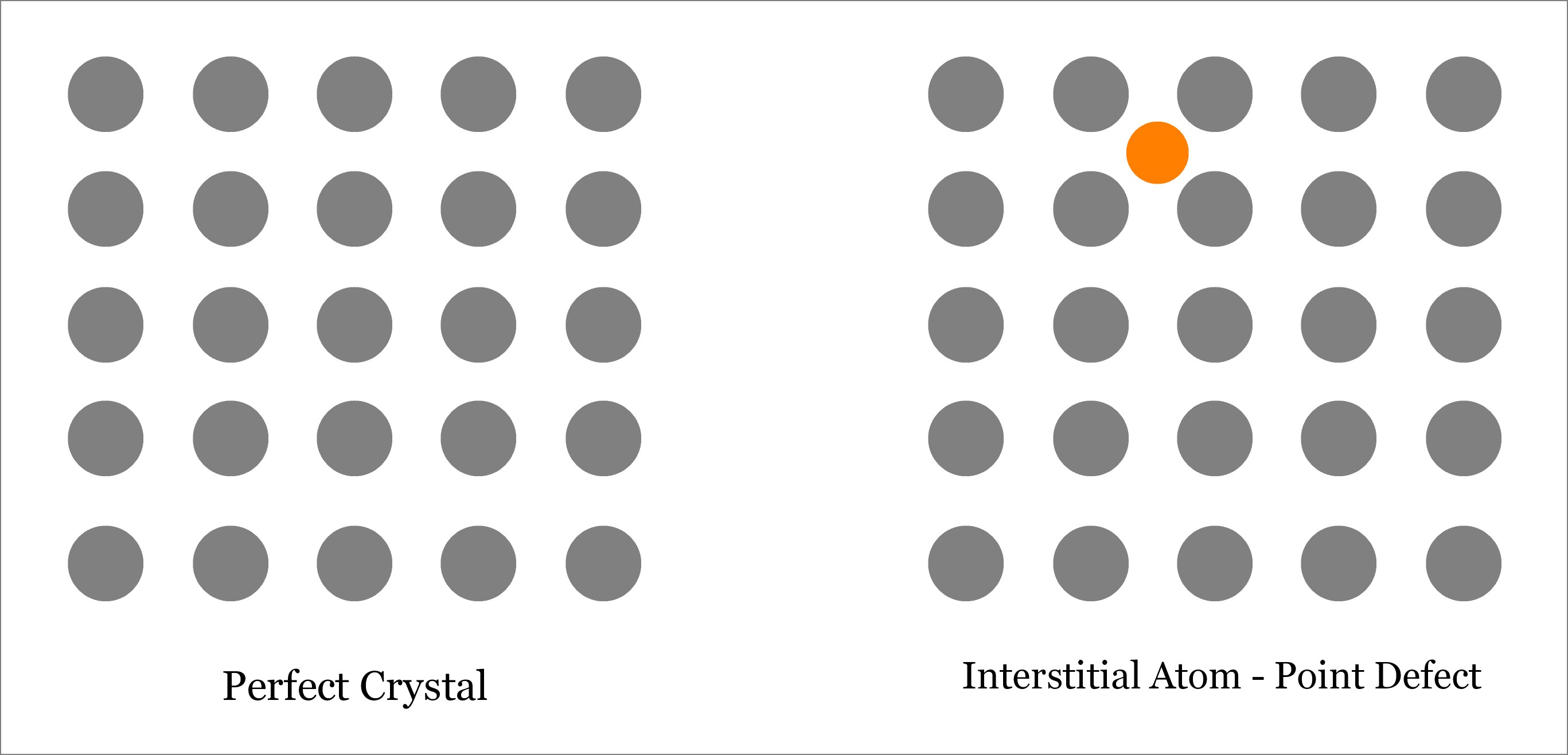

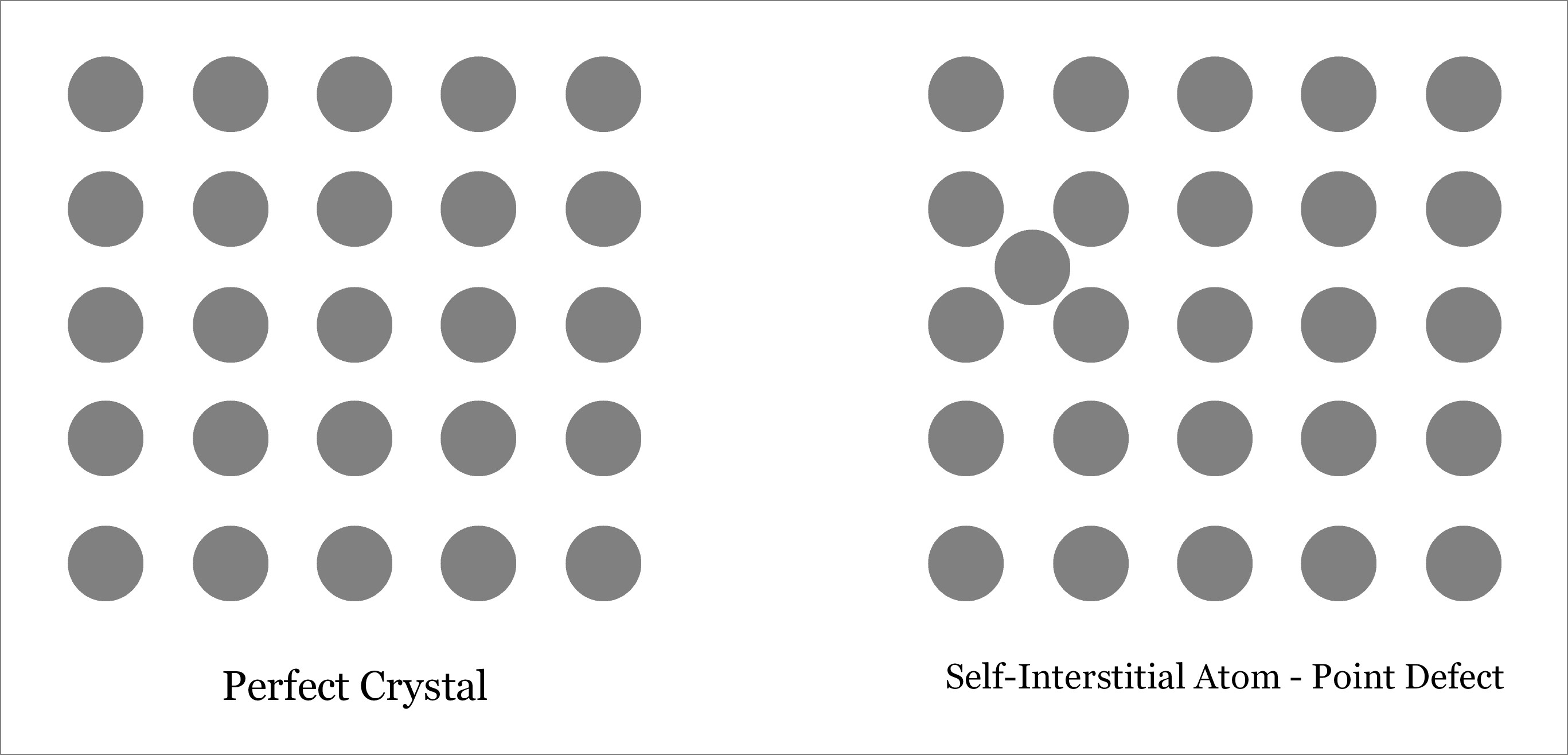

An interstitial defect occurs when an atom takes the interstitial position of the lattice structure. This interstitial atom may be of the same crystal or of a foreign material. Accordingly, interstitial defect can be of two types:

- Self-Interstitial Defect—occurs when atom of the same crystalline solid occupies the interstitial position leaving its original lattice site.

- Interstitial Defect—occurs when a foreign atom occupies the interstitial position.

Although extra atom occupies the empty interstitial space, the size of the atom is usually larger than that of the empty space. Thus the surrounding atoms are compressed and distorted. Presence of substantial number of interstitial atoms can change the mechanical and thermal properties of the solid. However, this is sometime beneficial, and thus interstitial defects can be applied in a controlled way to enhance various properties of the solid. For example, in steel production, carbon is added with iron.

Where interstitial defects can be found?

- During iron to steel production, carbon atoms occupy interstitial positions of the iron crystal.

- Similar thing happens in many alloys.

- In semiconductor materials.

Causes of interstitial defect in solids:

- Presence of foreign atoms as natural impurities within the solid.

- Deliberate addition, such as during iron to steel conversion, heat treatment, coating, etc.

- Diffusion, caused by close contact between two different materials.

Effects of interstitial defects:

- Although extra atom occupies the empty interstitial space, the size of the atom is usually larger than that of the empty space. Thus the surrounding atoms are compressed and distorted.

- Presence of substantial number of interstitial atoms can change the mechanical and thermal properties of the solid. However, this is sometime beneficial, and thus interstitial defects can be applied in a controlled way to enhance various properties of the solid.

- Presence of large number of interstitial atoms can even convert electrically non-conductive material to conductive one.