A single point cutting tool is characterized by the presence of only one active cutting edge in the tool body that participates in material removal action during machining. Turning tool, boring tool, parting tool, shaping tool, planing tool and fly cutting tool are examples of single point cutters. In contrary, a multi-point cutting tool contains several active cutting edges that simultaneously take part in machining. For example, milling cutter, reaming tool, broaching tool, grinding wheel, etc.

Pros and cons: A single point cutting tool offers several benefits, like (i) easy to design the cutter, (ii) easy to fabricate and re-sharpen the cutter, and (iii) cheaper. However, multi-point cutters also provides numerous advantages, like (i) can sustain high cutting force, (ii) higher chip load can be given, (iii) offers high material removal rate and thus productive, (iii) longer tool life, (iv) can inherently balance cutting force, vibration or deflection, etc. However, in majority of the cases, it is the specific machining operation that requires either a single point or a multi-point cutting tool without allowing any choice.

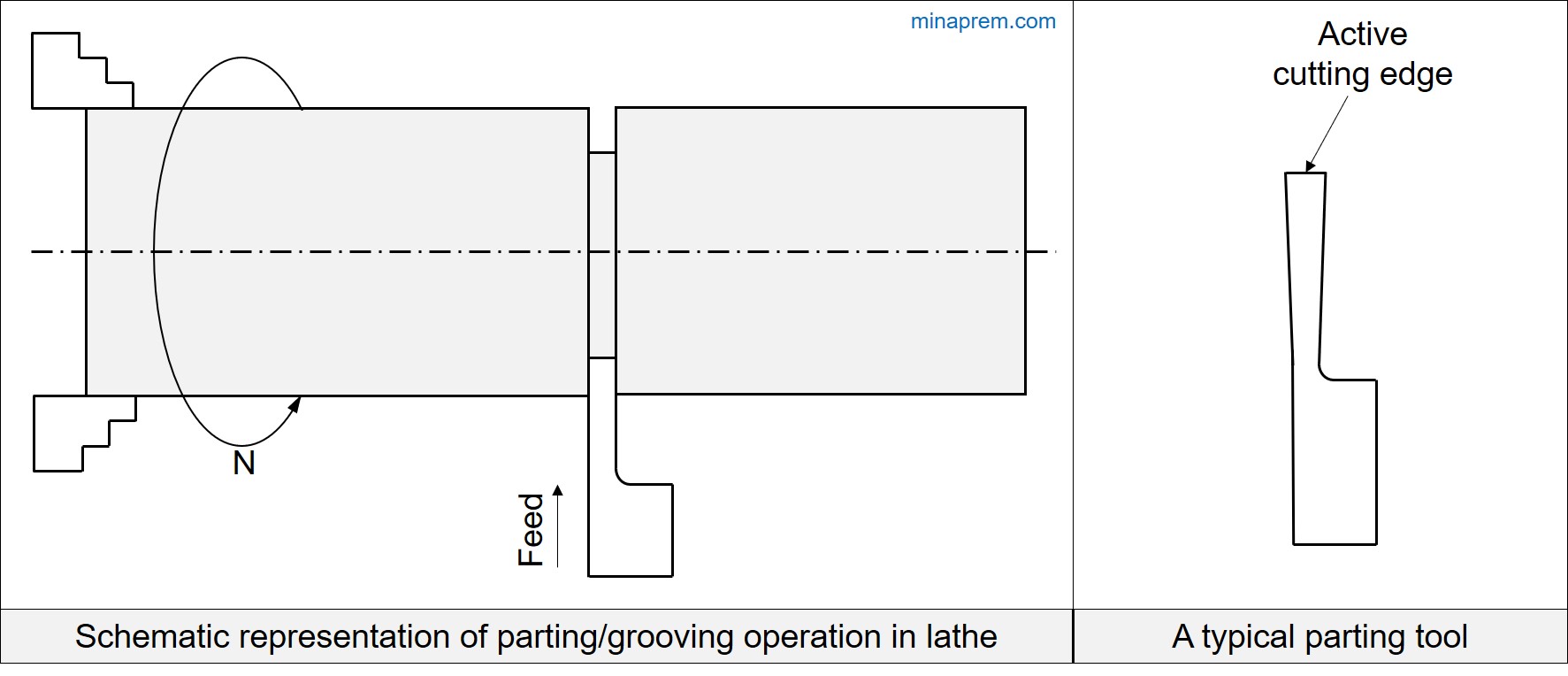

Parting off operation in lathe: Parting operation is carried out in lathe to separate the final job from the original blank. It can also create a cylindrical grove on the job rather than completely separating it. Although both the processes are same, the later one is termed as grooving. The parting process utilizes a thin parting tool that is mounted on the tool post using proper clamps. It is then fed in transverse direction against the rotating cylindrical workpiece at a pre-defined feed rate. As the tool plunges into the workpiece, a grove forms. If the requirement is a grove, then the tool is retracted once it is penetrated to the defined grove depth. If plunging it continued until the tool reaches the workpiece axis, then parting takes place. In case the workpiece is one hollow cylinder, then parting takes place once the tool is fed by the distance equal to the cylinder thickness.

It is worth mentioning that the feed in parting or grooving operation is provided in transverse direction (radial direction). Here the depth of cut remains constant and mostly parallel to the job axis. The thickness of the parting tool determines the depth of cut; in fact, they are equal. Moreover, the cutting velocity (m/min) does not remain constant during the parting operation as diameter of the job at cutting point decreases continuously due to presence of feed. However, in CNC based machine tools, the velocity can be maintained constant by proportionally increasing the rotational speed (rpm) of the workpiece. It differs from the straight turning operation where cutting velocity remains unchanged during operation. Also feed in straight turning is given in longitudinal direction and depth of cut is given in transverse direction.

The parting tool: Parting or grooving tool is a thin single point cutting tool that mostly has zero rake angle. The tool is made slightly tapered from top to bottom in order to provide necessary clearance angle. The thickness of the tool defines the grove width. Accordingly, varying width starting from 1/16 inch to 1/2 inch are readily available in market. Maximum groove depth is also limited by the length of active part of the parting tool. A longer active part allows cutting deeper grooves; however, with the sacrifice of strength and rigidity.

Material of parting tool: The parting tool is commonly made of High Speed Steel (HSS) to assist repeated sharpening (grinding). Grades like M2, M35 and T42 are quite popular. HSS parting tools allow use of low cutting velocity (up to 40m/min) and low feed rate, and thus are commonly applied when operation is carried out in manual lathe. However, tungsten carbide based coated inserts are also available in market. Such inserts are mounted in a specifically designed parting tool holder. These are suitable for hard and difficult-to-machine materials, and are frequently applied in CNC lathe or horizontal machining centre.