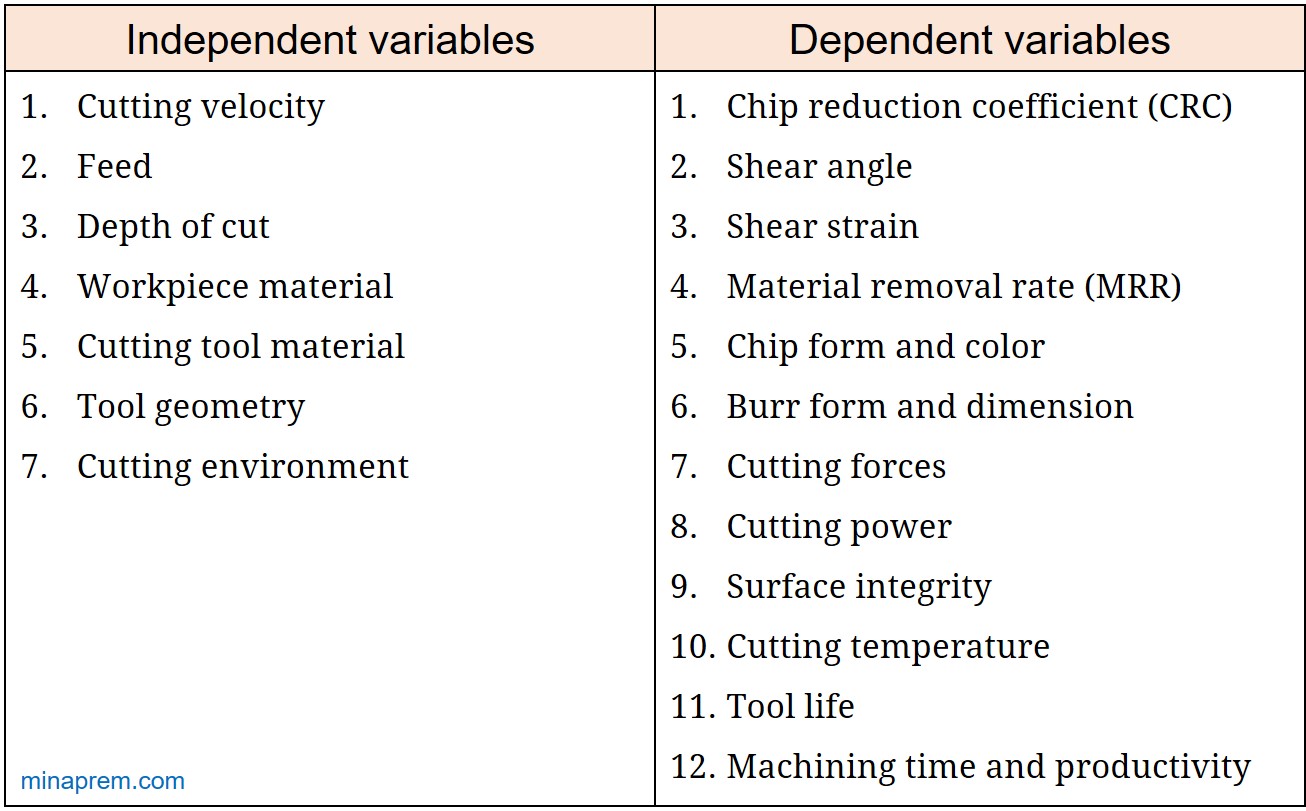

Machining or metal cutting is the process of gradual material removal from the workpiece with the assistance of a cutter. Quality of the machined object is not the only one parameter to judge machining performance. Independent variables are those that controls overall machining performance. Dependent variables are used to measure the machining or analyse overall machining performance. Thus dependent variables rely on independent variables. So independent variables can be altered prior or during machining in order to obtain desired result of one or more dependent variables. There are several dependent and independent variables as enlisted below.

Independent variables in machining

- Cutting velocity, normally denoted by Vc. Note that cutting speed is not same with cutting velocity. The velocity relies on rotational speed and diameter of the rotating object—either workpiece or cutting tool (based on machining process, for example, workpiece rotates in turning, whereas cutting tool rotates in drilling or milling). Cutting velocity, which is typically measured in m/min, is one crucial parameter in metal cutting).

- Feed, normally denoted by f or s. It has different units of measurement; however, all express the distance of movement of the workpiece or tool. Feed and feed rate are not exactly same, but they are interrelated. Feed rate indicates movement of the workpiece or tool per unit time. Feed is imparted on workpiece in some metal cutting operations (like milling); whereas, it is imparted on cutting tool in other operations (like turning, threading, drilling).

- Depth of cut, normally denoted by t or h—although it has least influence on several aspects, but is not always negligible.

- Workpiece material—several mechanical and thermal properties can influence machining capability. Such properties include ductility, hardness, shear strength, residual stress, grain orientation (especially in micro-cutting), thermal conductivity (influences diffusion wear rate), etc. Even presence of cracks and other defects can hamper machining performance. Wetting ability of the workpiece surface can also impact during wet machining.

- Cutting tool material—Several properties of the cutting tool material also influences machining performance. Such properties include strength, hardness, toughness, thermal stability, inertness, diffusion resistance, corrosion resistance, etc. Since a compatible tool material is usually selected based on the workpiece material, so it is better to say workpiece-tool material pair is one independent variable in machining.

- Cutting tool features and geometry—Not only materials, but also geometry of cutting tool can influence machining performance noticeably. Such features and geometrical parameters includes number of active cutting edges, rake angles, clearance angles, cutting edge angles, nose radius, edge radius, etc.

- Machining environment—Several situations are possible, like dry cutting (no cutting fluid is applied), minimum quantity lubrication or MQL assisted cutting (cutting fluid is applied in spray form), wet flood cooling (cutting region is always immersed into fluid), etc. The lubrication and cooling effects of the cutting fluid have immense impacts on machining performance.

Dependent variables in machining

- Chip reduction coefficient (CRC) or cutting ratio

- Shear angle

- Shear strain

- Material removal rate (MRR)

- Chip form and color

- Burr form and dimension

- Cutting forces

- Cutting power

- Surface integrity (most importantly surface finish)

- Cutting temperature

- Tool life

- Machining time and productivity