Cutting Tool is a wedge shaped device that actually removes (shears off) excess material from a preformed blank in order to obtain desired shape, size and accuracy. While machining or metal cutting operation, the cutter forcefully compresses a thin layer of material in the workpiece and gradually shears it off. However, to remove material, three relative motions are necessary. These motions actually provide necessary cutting velocity, feed velocity and depth of cut. Cutting tool itself cannot provide any such motion as it is rigidly mounted on the tool holder in machine tool. All necessary motions are supplied by machine tool using various arrangements.

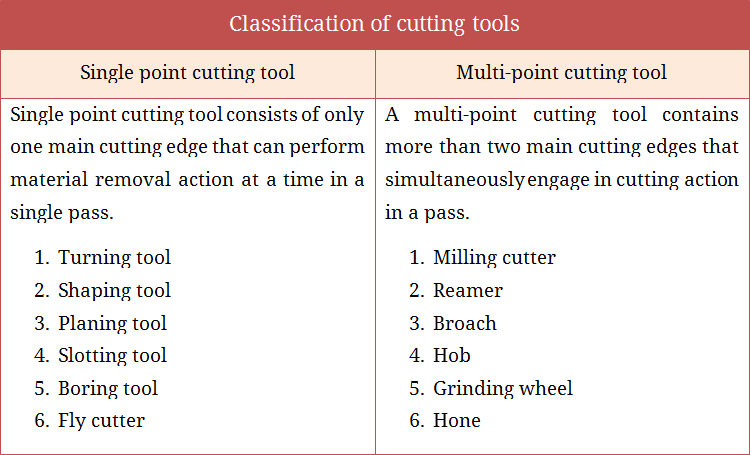

Classification of cutting tools

Although basic shape of cutting tool varies greatly with the type of operation it is intended to perform, every cutting tool must contains a wedge shaped portion with a sharp cutting edge, which can cut material smoothly. Now, a cutting tool may contain one or more main cutting edges that participate in cutting action at a time in a single pass. Cutting tools can be classified in various ways; however, the most common way is based on the number of main cutting edges that participates in cutting action at a time. On this basis, cutting tools can be classified into three groups, as given below.

- Single point cutting tool

- Double point cutting tool

- Multi point cutting tool

What is single point cutting tool?

Single point cutting tool consists of only one main cutting edge that can perform material removal action at a time in a single pass. It is to be noted that in insert based cutting tools, multiple cutting edges may present in a single tool; however, only one cutting edge can engage in material removal action at a time.

Examples of single point cutting tool

Turning tool, also known as Single Point Turning Tool (SPTT), is the perfect example of a single point cutter. SPTT has only one main cutting edge (called Principal Cutting Edge) arises from the intersection of rake surface and principal flank surface. Auxiliary cutting edge does not usually participate in cutting action, unless the feed rate and depth of cut are high. Apart from turning tool, few other cutters are also single point tool as enlisted below.

- Shaping tool

- Planing tool

- Slotting tool

- Boring tool

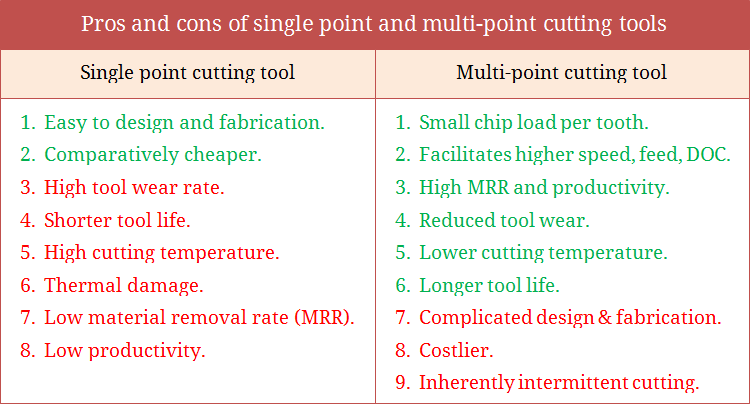

Advantages of single point cutting tool

- Design and fabrication of single point cutter is quite simple and less time consuming.

- Such tools are comparatively cheaper.

Disadvantages of single point cutting tool

- A single cutting edge continuously remains in physical contact with the work material during machining. So the tool wear rate is also high and as a result tool life is low.

- Due to continuous contact, rate of rise in tool temperature is high. This, in one hand accelerates tool wear and in other hand causes thermal damage of the finished/machined surface.

- High temperature rise may plastically deform the tool tip that can lead to poor accuracy in machining.

- Since only one cutting edge takes entire depth of cut (chip load) for a pass, the material removal rate (MRR) is much lower. Thus productivity is poor.

References

- Book: Machining and Machine Tools by A. B. Chattopadhyay.

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya.

- Book: Manufacturing Process for Engineering Materials by S. Kalpakjain and S. Schmid.

- Book: Geometry of Single-point Turning Tools and Drills – Fundamentals and Practical Applications by V. P. Astakhov.