Cutting tool is a wedge shaped sharp edged device that removes excess material by shearing from the workpiece during machining. Geometry, orientation and material of the cutting tool are three important factors that determine machinability (ease of machining) as well as quality of the machined product. Geometry of cutting tool consists of rake angles, clearance angles, auxiliary clearance angles, cutting angles, nose radius, etc. Rake surface of the cutting tool is the only chip flowing surface and the orientation of this rake surface is indicated by rake angles. Thus this is one of the crucial factors to judge machining performance.

What is rake angle in a cutting tool?

By definition, rake angle of a cutting tool is the angle of orientation of tool’s rake surface from the reference plane (πR) and measured on some other plane. Reference plane (πR) is a plane which is perpendicular to cutting velocity vector at any point on the cutting tool.

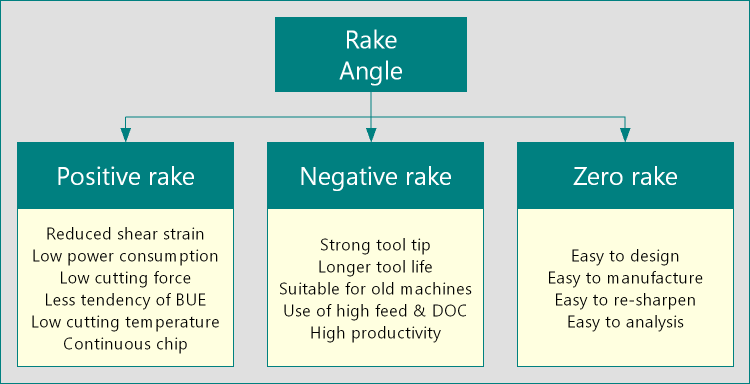

Depending on the orientation of rake surface with respect to reference plane, rake angle may be positive, negative or even zero, as elaborated in the following section. Each type has specific advantages and disadvantages. Value of the rake angles determines cutting force and power requirement, life of the cutting tool, chip deviation, etc. It also indirectly affects machinability.

Positive rake angle of a cutting tool

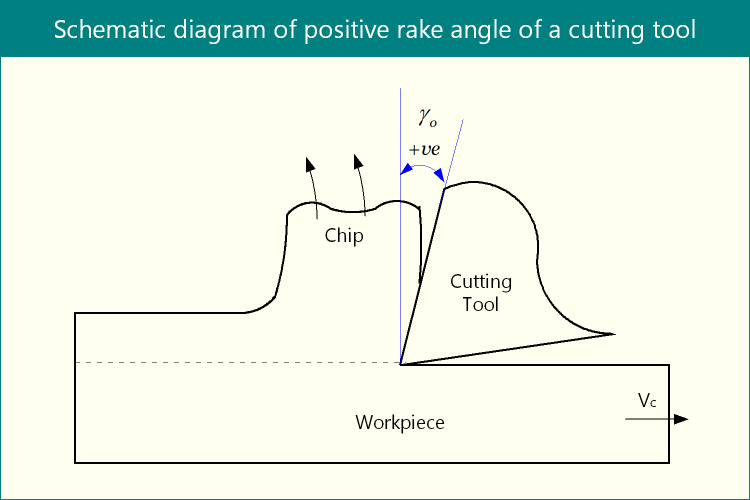

Positive rake angle implies the sum of the clearance angle and wedge angle is less than 90º. As schematically shown below, positive rake angle offers sharp cutting edge and thus less chip deformation during machining action. Cutting force and power requirement is comparatively less while machining with such cutting tool. It also helps in achieving better machinability by considerably reducing heat generation during machining.

However, due to small value of wedge angle, tool becomes prone to break and thus average tool life reduces. Any impact loading during machining may cause catastrophic failure of the tool, which is highly undesirable. High cutting temperature also makes such tool vulnerable under plastic deformation. Therefore, cutting tool with positive rake angle is beneficial where the workpiece material is ductile and soft as well as when continuous chip formation is desirable. Following diagram schematically represents a cutting tool with positive rake angle. Note that the diagram is drawn in orthogonal plane, so the rake angle is basically orthogonal rake angle (γo).

Advantages of positive rake angle

- Sharp cutting edge of the tool.

- Less cutting force requirement.

- Continuous chip production.

- Good machinability.

Negative rake angle of a cutting tool

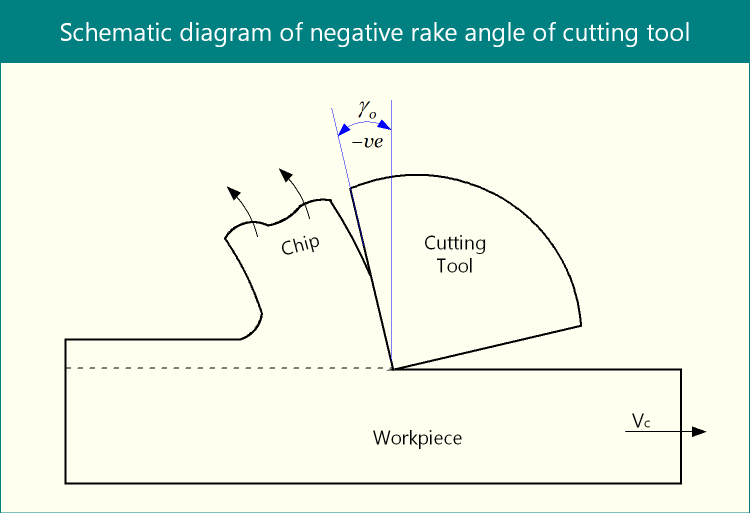

Opposite to the positive rake, negative rake offers a strong tool tip, which makes the tool more resilient under impact loading. It also resists plastic deformation at high cutting temperature because of the thick cutting edge which can absorb and at the same time dissipate more heat. Thus tool with negative rake provides longer tool life. However, due to large wedge angle, shear deformation of the chip becomes more and thus higher cutting force is required. Negative rake usually provides discontinuous chips, which is bad in terms of machinability.

Advantages of negative rake angle

- Strong tool tip.

- Resists catastrophic failure of the tool.

- Longer tool life.

- Helpful in machining hard materials.

Read more: Difference between positive rake and negative rake

Zero rake angle of a cutting tool

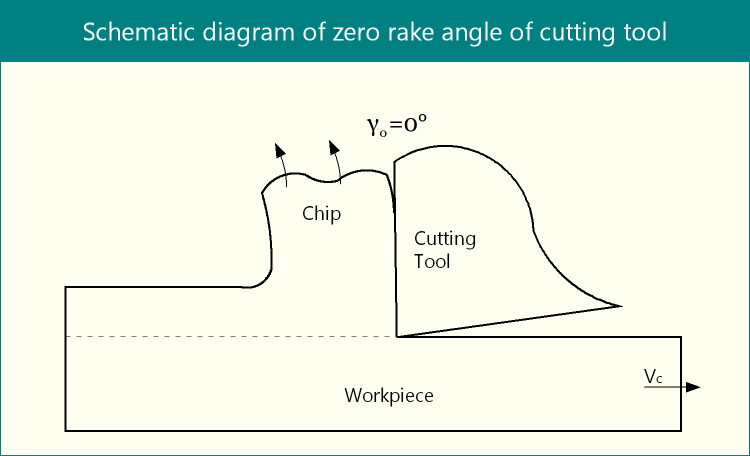

As shown in the figure, zero rake angle is in between the positive and negative rake angles. It can provide advantages of both of them; however, to some extent. Cutting tool with zero rake angle is easy to design and manufacture. Such tools also provide advantage while re-sharpening the tools. Thread cutting tools are usually provided with zero rake angle.

References

- Book: Principles of Mechanical Engineering by S. Singh (S. Shand).

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Book: Manufacturing Processes by J. P. Kaushish (PHI).

- Book: Manufacturing Science by M. I. Haque and S. Khan (PHI).