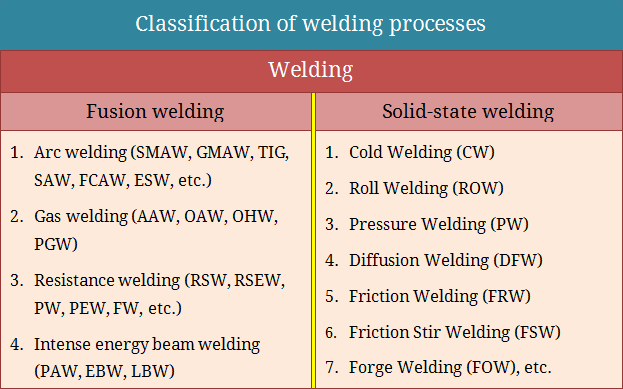

Welding can be defined as one of the manufacturing processes by which two or more similar or dissimilar materials can be joined permanently by coalescence formation with or without the applications of external pressure, heat or filler material. Fusion of faying surfaces of parent materials is not necessary for weld bead formation. On the basis that base material fuses or not, welding processes can be broadly classified into two groups—solid state welding and fusion welding. If faying surfaces of parent materials along with filler material melt down to form weld bead, it is termed as fusion welding. On the other hand, if no such melting takes place during welding, then it is termed as solid state welding.

What is solid-state welding?

In all those welding processes where melting of faying surfaces of parent materials don’t take place are called solid-state welding. Unlike fusion welding, here application of heat is not necessary. However, application of pressure is required for getting a sound joint and thus it is also termed as Pressure welding. It is worth nothing that sometime base materials are heated to an elevated temperature while joining by sold-state welding process; however, temperature always remains below melting point.

Examples of solid-state welding

Any welding process where no melting takes place comes under this group. Although fusion welding processes are many, there exist quite a few solid-state welding processes also. Some examples are provided below. Note that many people consider resistance welding group as solid-state welding; here the same is kept under fusion welding as nugget is formed due to melting of faying surfaces by resistance heating.

- Cold Welding (CW)

- Roll Welding (ROW)

- Pressure Welding (PW)

- Diffusion Welding (DFW)

- Forge Welding (FOW)

- Friction Welding (FRW)

- Friction Stir Welding (FSW)

- Explosion Welding (EXW)

- Ultrasonic Welding (USW)

Advantages of solid-state welding processes

- Because of no melting and solidification, these processes provide comparatively lower lever of distortion and residual stress generation.

- Heat affected zone (HAZ) is also narrower.

- It provides sumptuous weld appearance.

- Mechanical properties of parent materials remain intact as no fusion takes place.

- Easy to join dissimilar metals.

Disadvantages of solid-state welding processes

- It requires special type of joint design, edge preparation and/or surface finish.

- Primary shape of the components is crucial factor as pressure is needed to apply (a suitable shape is required to apply pressure uniformly).

- Joining more than two components at a time is difficult; in some cases it is impossible.

- Application of filler material is not possible. So wider root gap cannot be filled.