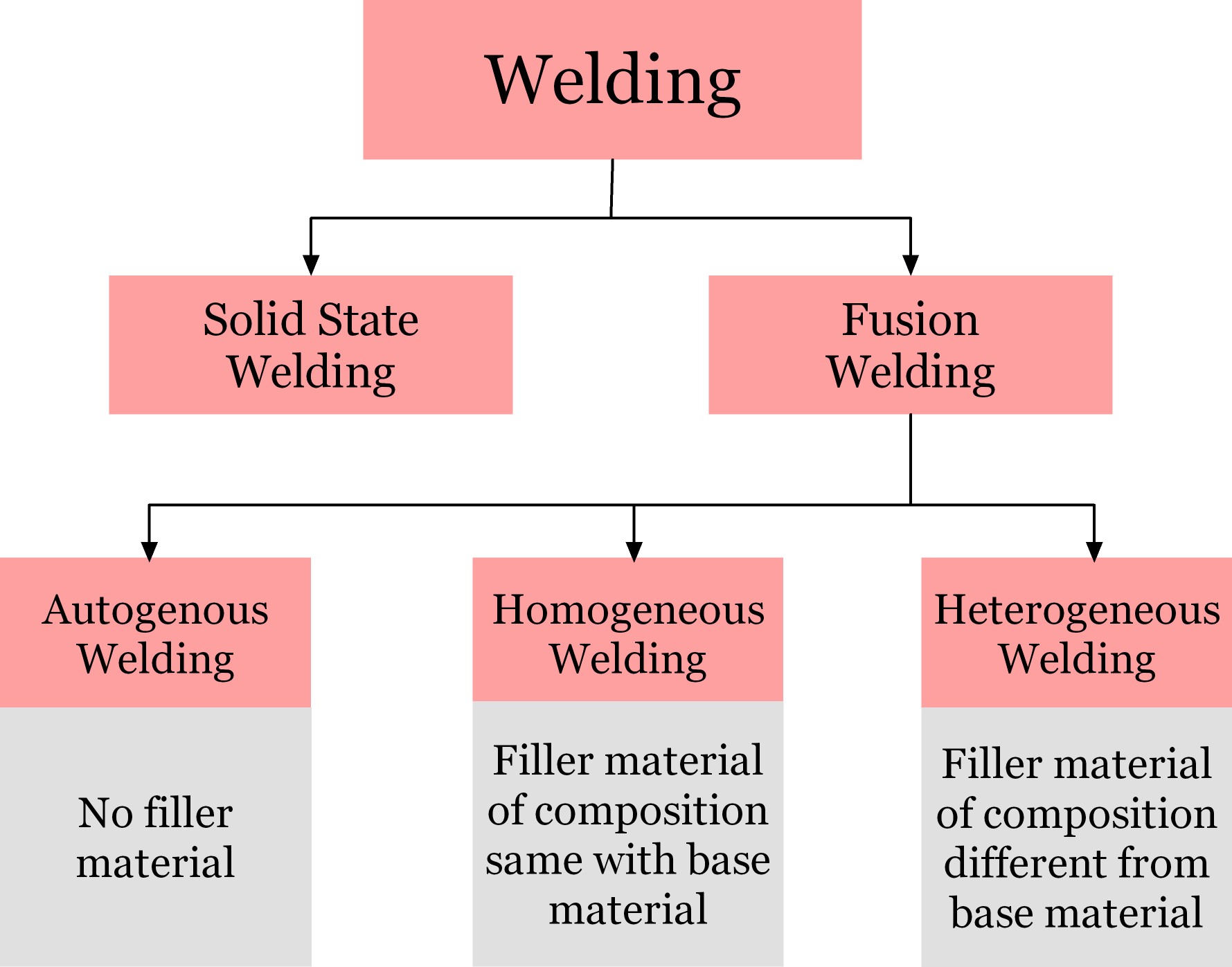

Welding processes can be broadly classified into two groups—Fusion welding and Solid-state welding. Fusion welding comprises all those welding processes where heat is directly applied from an external source in order to fuse or melt faying surfaces of base metals to form weld bead. This heat can be applied in various means, such as by electric arc, burning oxy-fuel gas, laser beam, etc. On the other hand, solid-state welding processes need external pressure to make joining. In such processes heat may inherently produce internally, but direct application of heat is not required for joining.

- Read more: Classification of welding processes.

Classification of fusion welding processes—Autogenous, Homogeneous & Heterogeneous

While joining by fusion welding processes, filler material can be applied during welding, if required. Due to the application of external heat, this filler material melts down and deposits on weld bead to supply excess material required for filling the root gap for obtaining a sound weld. It is to be noted that application of filler material is not necessary; it is usually applied when sufficient root gap exists or edge preparation is conducted. According to the application and nature of filler material, fusion welding processes can be grouped into three categories—Autogenous welding, Homogeneous welding and Heterogeneous welding.

What is autogenous welding? – Examples

Autogenous welding is one way of performing fusion welding without the application of external filler material. It is to be noted that autogenous welding is not a particular type of welding process like MMAW, TIG, GMAW, etc.; instead, it is one of the three different ways or modes of doing fusion welding. Note that solid state welding processes are usually autogenous as they don’t use any filler during welding.

Tungsten Inter Gas (TIG) and oxy-fuel welding processes can be performed in autogenous mode/way. Various advanced welding processes, such as Plasma Arc Welding (PAW), Laser Beam Welding (LBW), Electron Beam Welding (EBW), etc. are mostly autogenous. There are some fusion welding processes which cannot be performed in autogenous way. For example, Manual Metal Arc Welding (MMAW), Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), etc. always use consumable filler material and thus cannot be performed in autogenous way.

- Homogeneous welding – example, advantage & disadvantage.

- Heterogeneous welding – example, advantage & disadvantage.

Advantages of autogenous welding

- Fusion welding of thin sheets is possible only in autogenous way.

- No extra cost for filler material.

- Weld appearance is good.

- Processes can be easily automated.

- No post-grinding is required to remove reinforced parts.

Disadvantages of autogenous welding

- Only butt joint is possible and that too maintaining no root gap between parent parts.

- Thickness of the plates is also limited to only 2 – 3mm in order to obtain a sound welding.

- Strength of the joint is not good—it is less than the strength of base plates.

- As molten metal from base plates is used to fill the narrow gap between plates (root gap), welded part becomes slightly weaker (5 – 20% weak).

- These joints are crack-sensitive due to lack of molten metal supply during solidification.

- Cannot be applied for joining more than two parts as the later requires substantial amount of filler material.

- No edge preparation is allowed, i.e., only square edge.

- Complete removal of any oil, rust or scale is essential to obtain sound weld.